OVERVIEW

Vacuum or atmosphere tube furnace provide a vacuum, controlled atmosphere and high temperature experimental environment, applied in semiconductor, nanotechnology, fiber and other fields.

Vacuum or atmosphere tube furnace provide a vacuum, controlled atmosphere and high temperature experimental environment, applied in semiconductor, nanotechnology, fiber and other fields.

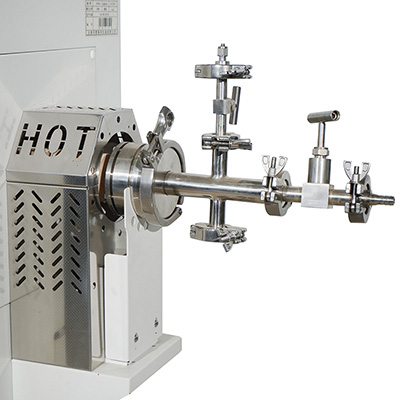

1. Quick connection flange structure is adopted for gas path connection, which is convenient for loading and unloading, and can be completed with only one clamp

2. The furnace is made of polycrystalline mullite fiber by vacuum adsorption, with uniform temperature field and energy saving of more than 50%

3. Independently developed air diversion heat insulation technology ensures the service life and constant temperature effect of all parts in the box

4. Start the electric furnace, and the exhaust fan will run automatically at the same time. After the test, the exhaust fan will continue to run until the temperature of the furnace body is lower than 60 ℃, and the exhaust fan will stop automatically, effectively protecting the surface of the furnace body

5. The gas circuit assembly is made of 316 stainless steel of food grade, with good corrosion resistance, atmospheric corrosion resistance, high temperature resistance, and non-magnetic

6. Automatic power-off, over temperature protection and leakage protection to ensure the safety of use

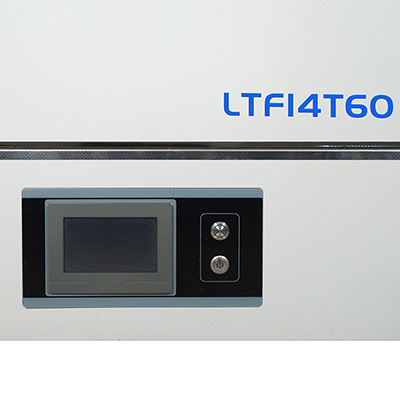

7. Imported program temperature control system, 4 curves, programmable 40 segment program temperature control, touch screen is 7 inch screen, built-in 50 formulas, 50 programs, formula name can be set by users, formula can be added, deleted and transferred at will

8. The circuit adopts continuous heating output mode, double circuit power supply, strong and weak current wiring separately, which improves the stability of the system

9. The heating module adopts DC signal to adjust the output power, so as to avoid the interference of induction current to the control signal

10. Low pressure metal button is selected as the operation button, with its own status indicator, which is safe and intuitive

11. It can automatically compensate the temperature control effect caused by temperature or aging on the resistance value of silicon carbide rod, so as to avoid the inaccuracy and danger of manual adjustment

Safety

Over rise alarm, menu locking, over rise prevention, power recovery delay

Model | Single zone | LTF14P40 | LTF14P50 | LTF14P60 | LTF14P80 | |

LTF14T40 | LTF14T50 | LTF14T60 | LTF14T80 | |||

Performance | Temp. Range | 300~1400℃ | ||||

Temp. Resolution | 1℃ | |||||

Temp. Uniformity | ±1℃ | |||||

Heating rate | 0-20 ℃ / min | |||||

heating zone | 200mm | 400mm | ||||

Constant temp zone | 70mm | 140mm | ||||

Maximum vacuum | - 0.1MPa | |||||

Structure | Shell | cold rolled steel plate, surface temperature treatment | ||||

Chamber materials | polycrystalline mullite fiber | |||||

Chamber size | 360*350*350 | 560*350*350 | ||||

Tube | alumina tube | |||||

Tube size | Φ40/34*1000 | Φ50/44*1000 | Φ460/50*1000 | Φ80/70*1000 | ||

Thermal insulation layer | double-layer forced wind diversion | |||||

Heating element | silicon carbide rod | |||||

Heating Power | 3kw | 5kw | ||||

Controller | Controller | P:Imported program controlled temperature digital display T:Seven inch color touch screen program temperature control | ||||

Control Mode | Microcomputer PID control /S type Separate temp control in double heating zone | |||||

Setting Mode | P: Slightly touch five buttons, digital setting mode T: Touch setting mode | |||||

Display Mode | P:Double row LED digital display T: Color LCD display | |||||

Timing | 0~999.9 hours | |||||

Operation Function | Set value run, program run | |||||

Program mode | P:Program operation, four curves, a total of 40 steps T:Maximum 50 steps, adjustable storage program | |||||

Sensor | K-type thermocouple | |||||

Auxiliary Function | P:correction function T: correction function, Real-time curve recording, U disk data export | |||||

Safety Device | over current and leakage protection switch | |||||

Specification | Dimensions | 1531*500*728mm | ||||

Package size | 1120*630*1060mm | |||||

Weight | 95kg | |||||

Power Supply | AC220V 50Hz | |||||

Standard Configuration | A set of gas circuit assembly (including vacuum gauge), A pair of high temperature gloves 1 alumina tube, 2 alumina plugs, 2 alumina boats, 1 hook | |||||