FEATURES

1.The furnace is made of polycrystalline mullite fiber vacuum adsorption, the temperature field is uniform and energy saving is more than 50%

2.The self-developed air diversion and heat insulation technology ensures the service life and constant temperature effect of each component in the box

3.When the electric furnace is started, the exhaust fan will automatically run at the same time. After the test, the exhaust fan will continue to run until the temperature of the furnace body is lower than 60 °C, and the exhaust fan will stop automatically, which effectively protects the surface of the furnace body.

4.The furnace door is opened with automatic power-off, over-temperature protection function, and leakage protection function to ensure the safety of use.

5.The circuit adopts continuous heating output mode, dual-circuit power supply, and separate wiring of strong and weak current improves the stability of the system

6.The heating module adopts DC signal to adjust the output power, which avoids the interference of induced electricity to the control signal.

7.Low-voltage metal buttons are used for operation buttons, with status indicator lights, safe and intuitive operation.

8.The upper and lower furnace bodies are connected by aviation plugs, which are safe, reliable and convenient to connect.

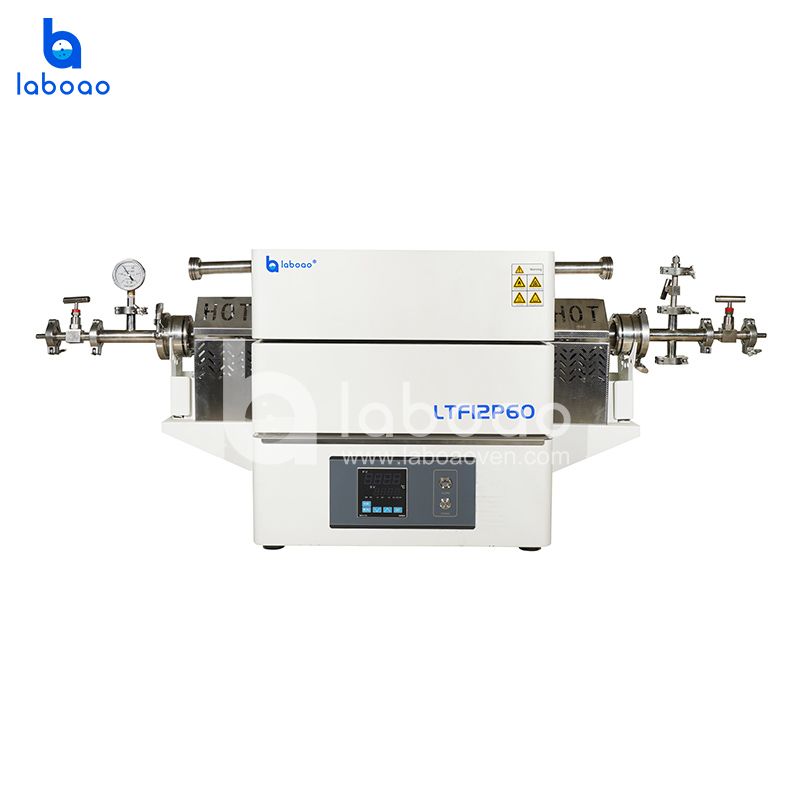

9.The gas circuit assembly is made of food grade 316 stainless steel, which has corrosion resistance, atmospheric corrosion resistance and high temperature resistance, and is non-magnetic

10.Adopt digital flow display instrument, cooperate with mass flow controller, collect data and control flow. It has the characteristics of good repeatability, fast response speed, stability and reliability. (Gas Mass Flow Control System)

11.Automatic control and manual control switching function, the automatic control mode can automatically open/close the vacuum pump through the set value, so that the container can be kept within a certain vacuum pressure range. Manual control mode uses the user to directly operate the vacuum pump via the vacuum pump on/off button. to meet the needs of different experiments. (Medium vacuum control system)

12.The solenoid valve slow start technology makes the solenoid valve open 10 seconds after the vacuum pump is turned on, so that the system pressure in the furnace tube is kept accurate, and it also ensures that the exhaust gas will not return to the furnace tube system to affect the experimental effect (medium vacuum control system)

13.Overheating alarm, menu lock, overheating prevention, power recovery delay.

14.Using one-way valve technology, the gas flow is controlled within a controllable pressure range to ensure safety.

15.The gas mixing tank device is adopted, so that the gas can be introduced into the working room after being fully mixed to ensure that it will not leak.